- About Us

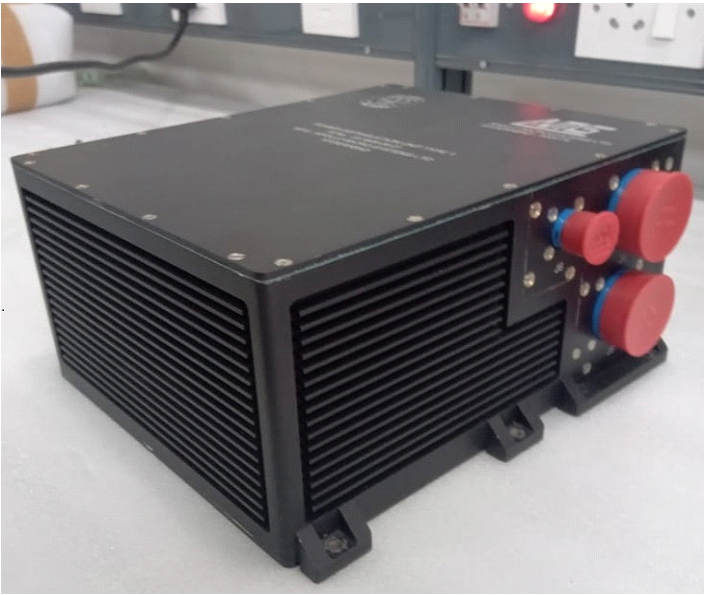

- Weapon Systems

- Products

- Services

- Infrastructure

- Careers

- Suppliers

- News

-

Investors

Investor Relations

-

Shareholders' Information

- Disclosures under Regulation 46 and 62 of SEBI (LODR) Regulations, 2015

- Corporate Governance Report

- Related Party Transactions Disclosure – Regulation 23(9)

- Reconciliation of Share Capital Audit Report

- Voting Results

- Scrutinizers Report

- Corporate Announcements

- Unpaid & Unclaimed Dividend

- BRSR Reports

- Postal Ballot

- Prospectus

- Board Meeting Outcome

- Notices of General Meetings

- Intimation of Record Date

- Certificates pertaining to Preferential Offer

- Financial Reporting

- Subsidiaries

- Shares

- Resource Centre

-

Shareholders' Information

- Contact Us

-